PERFECT DOT® QR

Users´ advantages

- True reproduction of the original copy

- Highest machine running speed

- Minimized gauge loss

- Extended lifetime

- Excellent easy clean features

- Suberb quick release properties

- Reduced running temperature

- Premium quality

Range of application

- In conventional sheetfed: for paper and carton

- Dual purpose, changing between conventl. and UV ink

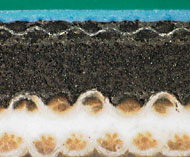

Cross cut of

PERFECT DOT® QR

PERFECT DOT® QR represents the further development of the well known PERFECT DOT® SR.

The improved quality contains an innovative compressible layer, manufactured utilising our new Dura-Elastic-Technology. With this feature the running temperature of the blankets is reduced resulting in enhanced inktransfer and dot reproduction with extended lifetime of the blanket.

The special surface grinding enables excellent sheet release, while the corresponding rubber mixture is an ideal solution for the changing use of conventional and UV inks.

In addition, the barrier layer within the double surface layer prevents the penetration of solvents and other chemicals thus reducing swelling.

Product data PERFECT DOT® QR

Surface roughness according to DIN 4768,

mechanical measuring system

Ra: 0.9 µm

Rz: 5.2 µm

Hardness according to DIN 53505

Top layer: 66 IRHD-micro

Total: 81 Shore-A

Thickness according to ISO 4593:1993: 1.95 mm

Tensile strength: >4,000 N/50 mm

Stretch according to ISO 12636-4.2

at 500 N/50 mm: 0.76 %

at 1,000 N/50 mm: 1.07 %

Compressibility according to ISO 12636-4.5

1st cycle: 7.0 %

5th cycle: 7.6 %

Printing pressure

at 0.10 mm impression: 100 N/cm2

at 0.20 mm impression: 180 N/cm2

Color of top layer: green

Surface: finest grinding