PERFECT DOT® TP

Users´ advantages

- Good solids and halftones

- High reduction of pressure marks (streaks)

- Excellent smash resistance and recovery

- Low gauge loss on cylinder

- Extended lifetime

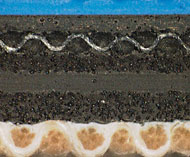

Cross cut of

PERFECT DOT® TP

PERFECT DOT® TP – the most innovative blanket available today for offset presses – TP comprises of a 1.95 mm blanket, with two completely new designed compressible layers.

PERFECT DOT® TP's unique construction enables the introduction of two compressible layers to produce optimum performance for the printing of good solids and the reduction of pressure lines which often occur with solids. With TP´s new design it is now possible to utilise Dual-Air-Technology without compromising either feature.

Extensive research led to the development of an improved blanket, that employs two compressible layers working together in one carcass.

The first compressible layer produces exceptional printing quality with solids and halftones while the second compressible layer reduces visible pressure lines and provides exceptional smash recovery leading to extended life time of the blanket.

PERFECT DOT® TP is suitable for printing on both paper (especially recycled paper) and carton up to 280 g.

Product data PERFECT DOT® TP

Surface roughness according to DIN 4768,

mechanical measuring system

Ra: 1.1 µm

Rz: 5.4 µm

Hardness according to DIN 53505

Top layer: 55 IRHD-micro

Total: 78 Shore-A

Thickness according to ISO 4593:1993: 1.95 mm

Tensile strength: >3,000 N/50 mm

Stretch according to ISO 12636-4.2

at 500 N/50 mm: 1.20 %

at 1,000 N/50 mm: 1.60 %

Compressibility according to ISO 12636-4.5

1st cycle: 7.8 %

5th cycle: 8.5 %

Printing pressure

at 0.10 mm impression: 95 N/cm2

at 0.20 mm impression: 152 N/cm2

Color of top layer: blue

Surface: finest grinding